With GIPI’s commitment to delivering highest quality products, corrosion protection is a critical element contributing to the lifespan of steel pipelines. When Carbon steel pipelines are invariably exposed to some type of corrosive environment, a corrosion protection is required which could be as simple as external paint or sophisticated internal and external coatings supplemented by a catholic protection system.

GIPI is an industry leader in the technology application of protective coatings and linings to steel pipes offering the following systems.

Fusion Bonded Epoxy Coating

Surface preparation of pipes includes removal of all surface moisture by passing pipes through a heating ring and flame, impinging all surface contaminants.

Prepared pipe passes through a process of wire brushing and vacuuming before the application of chromate pre-treatment. This is followed by induction heating which reaches a temperature between 180°C – 240°C prior to processing through an electrostatic spray booth. Full curing takes place within seconds with inspection commencing once surface temperature has reduced to a hand touch level.

3-Layer Coatings

A first layer of Fusion Bonded Epoxy (FBE) is applied. Thereafter a high performance protective adhesive layer is applied to the FBE coating which bonds to the final coat of either Polyethylene or Polypropylene.

Liquid Epoxy Lining

A thorough process of surface preparation is conducted. Liquid epoxies, solvent borne and solvent free are applied to the pipe inner surface through a lance and spray nozzle. For solvent free epoxies the two components are heated to 60 °C using heated water jackets along the lance to the mixing nozzle.

For solvent borne products premixed epoxy is pumped through a spray nozzle using airless spray equipment.

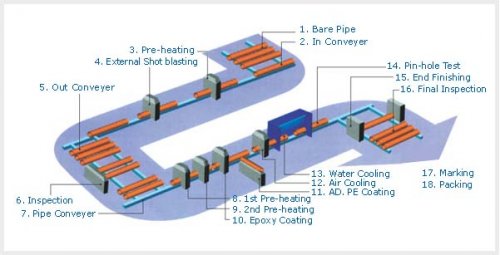

Manufacturing process